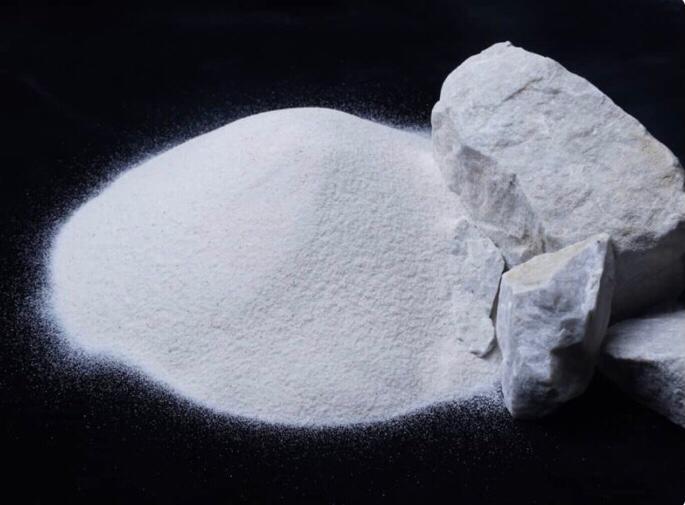

The particle size distribution of this product is similar to that of SFJ-PLD, which is known for its precise grading and exceptional quality. However, this product is additionally purified using a neodymium magnet to remove iron and other possible free iron compounds, ensuring the quality of colorless and transparent glass.

SFJ-PLDMD: Innovation in Safety and Processability with Dust-Resistant Micronized Silica

The SFJ-PLDMD product is an engineered solution to one of the biggest challenges in industries using micron powders: dust control. It retains all the premium quality features of SFJ-PLDMO ultra-pure silica—high purity, ultra-low iron, and exceptional whiteness—with one key difference: the addition of a precisely controlled moisture content (~0.5%) through an exclusive proprietary process.

This controlled moisture lightly binds the micron-sized particles together, preventing them from becoming airborne during handling, unloading, and mixing. The result is a safer working environment, reduced material loss, and significantly improved performance in automated production processes.

Processed using advanced SANDVIK and AKW production lines, SFJ-PLDMD sets a new standard in occupational safety and health (HSE) while maintaining the precise particle size distribution and exceptional quality comparable to SFJ-PLDMO.

Particle Size Comparison:

The particle size distribution of SFJ-PLDMD is similar to SFJ-PLDMO, offering precise grading and outstanding quality. The main difference lies in iron content: SFJ-PLDMD is virtually free of iron and other iron compounds, which maximizes the quality of clear and colorless glass products.

SFJ-PLDMD: Innovation in Safety and Processability with Dust-Resistant Micronized Silica

The SFJ-PLDMD product is an engineered solution to one of the major challenges faced by industries using micron powders: dust control. It retains all the premium quality features of SFJ-PLDMO ultra-pure silica—high purity, ultra-low iron, and exceptional whiteness—with one key difference: the addition of a precisely controlled moisture content (~0.5%) through a proprietary process.

This controlled moisture lightly binds the micron-sized particles together, preventing them from becoming airborne during handling, unloading, and mixing. The result is a safer working environment, reduced raw material loss, and significant improvements in automated production processes.

Processed using advanced SANDVIK and AKW production lines, SFJ-PLDMD sets a new benchmark in occupational health and safety (HSE) while maintaining all the superior qualities of ultra-pure micronized silica.

Chemical Analysis Table – Silica Sand (Code: PLDMD)

| Compound | Content (%) |

|---|---|

| SiO₂ | 99.31 |

| Al₂O₃ | 0.15 |

| CaO | N.D (Not Detected) |

| Fe₂O₃ | 0.05 |

Sample Code: PLDMD

Summary & Description

Sample Type: High-purity silica sand.

Main Purity: Extremely high silica content (99.31 % SiO₂) indicating excellent product quality.

Key Impurities: Only trace levels of aluminum oxide (Al₂O₃) and iron oxide (Fe₂O₃); calcium oxide (CaO) was not detected.

Silica Sand Particle Size Distribution (Code: PLD)

| Mesh No. | Size (mm) | Size (µm) | Sample (%) | Cumulative (%) |

|---|---|---|---|---|

| 10 | 2.0 | 2000 | 0.0 | 0.0 |

| 14 | 1.4 | 1400 | 0.0 | 0.0 |

| 18 | 1.0 | 1000 | 0.0 | 0.0 |

| 35 | 0.5 | 500 | 2.2 | 2.2 |

| 40 | 0.4 | 400 | 8.7 | 10.9 |

| 50 | 0.3 | 300 | 36.0 | 46.9 |

| 80 | 0.17 | 177 | 37.7 | 84.6 |

| 100 | 0.15 | 150 | 4.2 | 88.8 |

| 120 | 0.12 | 120 | 7.0 | 95.8 |

| 170 | 0.09 | 90 | 4.2 | 100.0 |

| 230 | 0.06 | 60 | 0.0 | 100.0 |

| 400 | 0.03 | 30 | 0.0 | 100.0 |

| Pan | Pan | Pan | 0.0 | 100.0 |

Explanations and Results

Title: Particle Size Distribution of Silica Sand (Code: PLD)

Columns:

Mesh No.: Aperture size of the sieve.

Size (mm): Particle diameter in millimeters.

Size (µm): Particle diameter in microns.

Sample (%): Percentage retained on each sieve.

Cumulative (%): Percentage of the total sample that passed through each sieve.

Key Findings:

More than 95% of the particles fall within the 0.09 to 0.5 mm range (Mesh 35 to 170).

The highest fraction (36%) is retained on Mesh 50 (0.3 mm).

The sample is free of oversized particles (>0.5 mm) and ultrafine particles (<0.03 mm).

This particle size distribution is suitable for industrial applications such as sandblasting, filtration, or silicon production.