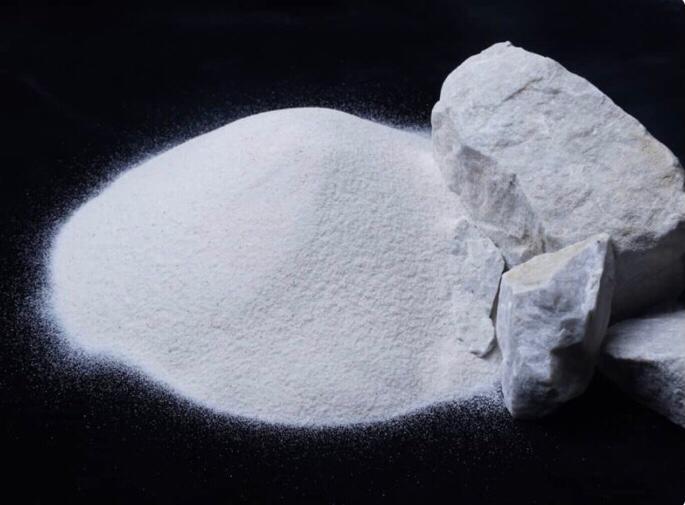

The particle size distribution of this product is similar to that of SFJ-PLD, which is known for its precise grading and exceptional quality. However, this product is additionally purified using a neodymium magnet to remove iron and other possible free iron compounds, ensuring the quality of colorless and transparent glass.

Purchase of Premium Low-Iron Silica

SFJ-PLDMO: The Pinnacle of Micronized Silica Technology for Specialized Applications

The SFJ-PLDMO, also known as premium low-iron silica, goes beyond industry standards. It is an ultra-pure silica that, in addition to being processed through SANDVIK and AKW production lines, undergoes advanced micronization. This process reduces particle size to the micron scale, resulting in a product with a high specific surface area, highly precise particle size distribution (PSD), and unique physical properties.

Through exceptional control of color-imparting impurities such as iron oxide (Fe₂O₃ < 0.025%) and titanium oxide (TiO₂ < 0.02%), this product guarantees outstanding whiteness and brightness. These characteristics make SFJ-PLDMO the ideal raw material for highly demanding industries, including paints and industrial coatings, polymer composites, advanced ceramics, and specialized sealants.

Chemical Specifications – Product Code: PLDMO

| Chemical Property | Percentage (%) | Technical Significance (Why It Matters) |

|---|---|---|

| SiO₂ (Silica) | 99.03 | Exceptional purity: ensures chemical stability, high hardness, and excellent dielectric properties in the final product. |

| Al₂O₃ (Alumina) | 0.15 | Improves mechanical properties: enhances wear resistance and strength in composites and engineering ceramics. |

| CaO (Calcium Oxide) | 0.17 | Alkalinity control: influences pH and reactivity, contributing to thermal stability and product performance. |

| Fe₂O₃ (Iron Oxide) | 0.07 | Very low iron content: critical for achieving maximum whiteness and brightness in paints, coatings, and plastics, preventing yellowing over time. |

| TiO₂ (Titanium Dioxide) | <0.02 | Precise color control: titanium is a strong pigment; maintaining it at very low levels is essential for absolute whiteness and color stability. |

Sample Code: PLDMO

Sieve Analysis – Silica Sand (Code: PLD)

| Mesh No. | Size (mm) | Size (µm) | Sample (%) | Cumulative (%) |

|---|---|---|---|---|

| 10 | 2.0 | 2000 | 0.0 | 0.0 |

| 14 | 1.4 | 1400 | 0.0 | 0.0 |

| 18 | 1.0 | 1000 | 0.0 | 0.0 |

| 35 | 0.5 | 500 | 2.2 | 2.2 |

| 40 | 0.4 | 400 | 8.7 | 10.9 |

| 50 | 0.3 | 300 | 36.0 | 46.9 |

| 80 | 0.17 | 177 | 37.7 | 84.6 |

| 100 | 0.15 | 150 | 4.2 | 88.8 |

| 120 | 0.12 | 120 | 7.0 | 95.8 |

| 170 | 0.09 | 90 | 4.2 | 100.0 |

| 230 | 0.06 | 60 | 0.0 | 100.0 |

| 400 | 0.03 | 30 | 0.0 | 100.0 |

| Pan | Pan | Pan | 0.0 | 100.0 |

Summary and Particle Size Description

Sample Type: Silica Sand

Sample Code: PLD

Key Particle Size Characteristics:

Coarse particles (retained on Mesh 35): 2.2%

Main particle fraction (between Mesh 40 and 120): 92.6% (8.7 + 36.0 + 37.7 + 4.2 + 7.0)

Fine particles (passed through Mesh 170): 4.2%

Dominant particle size: 0.3 mm (300 µm) to 0.17 mm (177 µm), comprising 73.7% of the total sample.

Note: The “Total (%)” column represents cumulative passing (%) through each sieve.